Canabec’s winning slice

By Mark Cardwell

Food Trends Meat &Poultry Canabec Editor pick Game meat QuebecIn a competitive market, the meat company’s focus on diversification and innovation has ensured growth

Canabec processes fresh and frozen pre-cut meats and precooked meals to confits, terrines, and deli. Photo © Canabec

Canabec processes fresh and frozen pre-cut meats and precooked meals to confits, terrines, and deli. Photo © Canabec In December 2023, Canabec started selling a new line of pate in tubes, which is not just another novel retail product from the innovative Quebec-based game meat maker, but the realization of a family’s food business dream. It was Canabec’s ‘national coming out’ party through Loblaws and Costco.

“My dad had a vision that’s reflected in our company name,” said Alexandre Therrien, owner, president, and CEO of Canabec. “He saw a Quebec company that supplies Canada with game meats. It’s been a long time coming but we’re finally there.”

From the first few carcasses of red deer that his father and company founder Laurier Therrien initially imported from New Zealand in 1987, Canabec today processes around 15,000 kg a week of mostly game meat at its plant in an industrial park in Saint-Augustin-de-Desmaures, a village just west of Quebec City.

Over the years, the company has developed a range of specialty meat products for high-end restaurant chefs across Quebec and, increasingly, for everyday consumers across Canada. Those products range from fresh and frozen pre-cut meats and precooked meals to confits, terrines, and deli. In addition to conventional meat and poultry protein, Canabec uses meat from a dozen exotic farm and game animals to make its products. Those species range from mostly Canadian-supplied duck, goose, rabbit, bison, elk, wild boar, guinea fowl and ostrich to imported kangaroo from Australia.

Canabec has also developed several retail products over the past 15 years that are carried by all major food store chains and specialty meat shops across Quebec. Its two best-selling items are raw Chinese fondue meats and pre-cooked confit duck legs, which are sold two to a box.

“I’m very happy and super excited by how things are working out for us these days,” said Therrien. “We’ve worked hard to develop new products and to diversify our offering. It’s helped us stand out in what is a very competitive but growing meat protein niche market.”

That market didn’t exist when Therrien’s father first imagined the culinary and commercial possibilities of wild game.

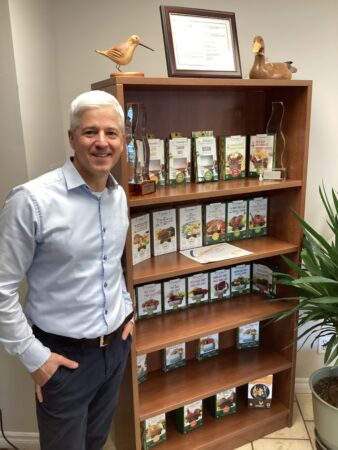

Alexandre Therrien.

Beginnings

Born and raised in the asbestos mining town of Thetford Mines, a 90-minute drive south of Quebec City, Laurier trained and worked as a chef in Montreal and Europe in the 1970s. He struck out on his own in 1978 when he and wife, Chantale Miclette, opened La Tanière, a gourmet restaurant that served haute cuisine dishes made with wild game deer, elk and seal on a remote rural road in Cap-Rouge, a 5-minute drive from Canabec’s current location.

“Dad ran the kitchen, mom handled the front,” said Therrien, who was only one when his La Tanière opened. Both he and his younger brother Frédéric worked in the business growing up, helping in the kitchen, bussing tables and doing whatever their parents needed. The same thing happened when their father created Canabec and started importing red deer carcasses from New Zealand. Initially, the business was run out of a small addition at the back of the restaurant with a C1 meat cutting certification where meat was prepared, packaged, and shipped to high-end eateries and speciality meat shops. As demand grew, Laurier moved Canabec into a 5000-sf facility in the Quebec City neighbourhood of Saint-Émile.

“Dad’s goal was to make more value-added products and cuts for his customers,” said Therrien. “The added space allowed him to diversify our game offering and expand our product lines.”

Game additions included quail, pheasant, and caribou from Northern Quebec. Canabec also developed several high-end deli products like terrines, mousses, and duck rillettes. It also began selling fresh cuts of red deer, bison, caribou and wild boar.

“Dad developed the market in Quebec City first,” said Therrien. “Then he went all across the province by adding a sales rep and a delivery truck.”

Canabec processes fresh and frozen pre-cut meats and precooked meals to confits, terrines, and deli.

With business booming, Laurier sold La Tanière in 2001 to focus on Canabec. The following year, however, Laurier suffered a heart attack at the age 50 and had to wind down his business activities. Therrien stepped up and took on more responsibilities at Canabec. At that time, the business focused on foodservice. Slowly, Canabec started to manufacture products for the grocery sector, which is challenging for game meat. They’re more expensive than other meats.

“Price point is the key,” said Therrien. “That’s why we decided to diversify by adding cheaper protein like pork to some of our products.”

Canabec processes around 15,000 kg a week of game meat at its plant in Quebec. Photo © Canabec

Retail debut

The company’s first grocery store product was sliced terrine. It went on sale in Quebec Sobeys stores in 2008. A few years later Canabec launched its first line of thinly sliced game meat for Chinese fondue or Chinese hot pot, a popular French-Canadian meal.

“I saw it as an opportunity and a way to make game meat more accessible to consumers,” said Therrien. “We developed some techniques that allowed us to thinly slice frozen game meats at –2 C. Any colder than that it flakes. Game meat is very lean. It has to be processed quickly to retain its original colour, texture and taste.”

Canabec’s Chinese fondue meats proved to be a hit with Quebec consumers. “It’s been one of our biggest successes,” said Therrien. In 2017, he moved the company to the 50,000-sf plant it now calls home.

The new plant carries many new machines and features that Therrien says have allowed the company and its 82 employees to make productivity gains in everything from processing, logistics and distribution to butchering, cuts and on-site cooking. New and automated equipment include three thermo former vacuum packaging machines, several cooking ovens, steam cooking equipment, kettles as well as vapour tumblers to thaw frozen meat. Other key pieces include a meat grinder, a boxing machine, and a package labeller.

In 2020, Canabec acquired the federal meat processing license, which brought about big changes at the company.

“It’s created a different culture,” said Therrien. “Before that we were more focused on taste profiles and customer service, notably on developing complex recipes and products to please our restaurant chef clients. We were not thinking like a food manufacturing company. We had to simplify, rationalize and streamline the process to make things less complicated and reach higher volumes. Now, security is the No. 1 issue in our manufacturing process. We needed to rethink our recipes and ingredients and processes in order to be compliant and to control or eliminate allergens like pistachios in duck confit.”

He said the company’s bestselling item in recent years has been Confit Duck Legs which, like guinea fowl, are cooked in duck fat in sealed bags and sold two to a box. Retail products now account for 75 per cent of company sales.

“Every meat has a different reaction to heat and different cooking times; it takes time and experience to get it just right,” said Therrien. “Our competitive advantage comes from our knowledge and experience with game meats and the vacuum cooking process. We plan to continue focusing on the retail side of the business. But we also do some private label. I’d like to increase that business by 15 to 20 per cent in the next two or three years.”

This article was originally published in the February/March 2024 issue of Food in Canada.

Print this page