Festo packaging two key systems so machine designers can shrink project footprints

MISSISSAUGA, Ont.—Festo is addressing the desire of machine designers for more compact control cabinet solutions to house key electrical and pneumatic control and monitoring systems in order to minimize project footprints.

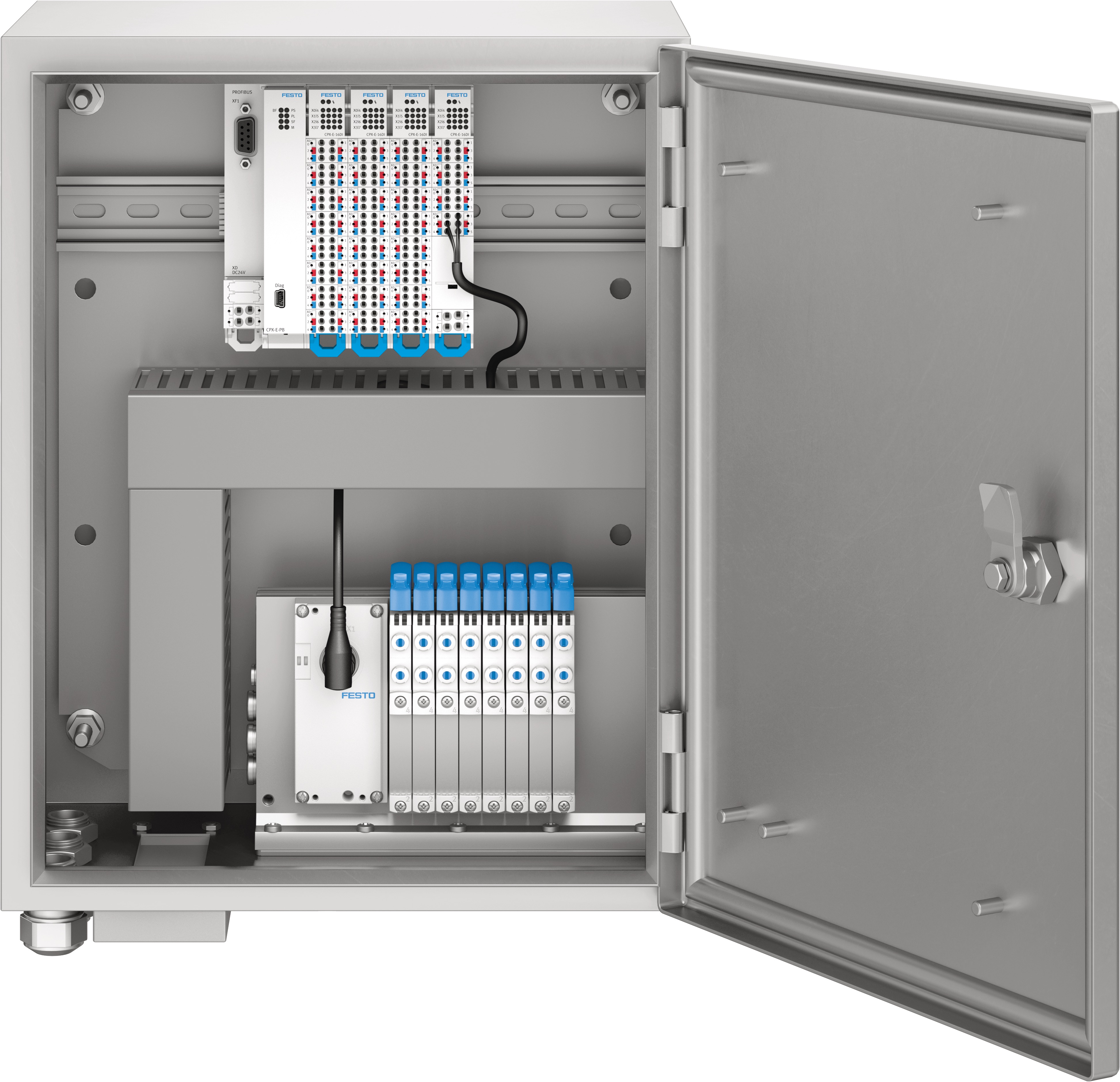

Festo’s compact VTUG plug-in valve terminal and CPX-E master/modular control system now can be ordered as a package. They fit comfortably together inside a very small cabinet—an intelligent use of space that’s more economical than comparable control cabinet solutions.

Festo also has made a number of enhancements to the VTUG plug-in, making it even more suitable for control panel installations used in the process or food and packaging industries.

These features include new panel mount manifolds, back pressure check valves, hot -swap module, and fixed flow restrictors. These new manifolds eliminate the need for actuator tubing within the cabinet, reducing panel size, assembly labour and cost. The supplied sealing gasket offers IP69K protection.

The VTUG’s practical hot-swap function allows individual valves to be replaced quickly during operation without the valve terminal having to be depressurized causing a potential loss of production time. VTUG offers up to 24 valve positions in a fixed grid and two possible functions per valve when 2x 3/2-way valves are selected. The VTUG can communicate to the most common fieldbus networks including PROFINET, and EtherNet/IP.

Also new: a DXF contour template available when the VTUG is configured online. This template reduces the engineering time required to create the panel production drawings

For its part, Festo’s new CPX-E modular control system consists of individual function modules which enable a flexible, modular design: depending on the module combination, the system can be configured as a purely remote I/O system with bus module or as a control system with integrated control unit.

The CPX-E‘s distinguishing features are its rapid signal processing, compact design and economical cost.

Festo at a glance

Festo, a leading global supplier of automation technology and technical education, is deploying its products and services to meet the challenges of digitization and smart production. Established in 1925, the independent, family-owned company based in Esslingen, Germany, has been a driving force in automation for over 60 years. Some 300,000 customers worldwide in factory and process automation put their trust in the company’s pneumatic and electric drive solutions. In addition, Festo Didactic provides state-of-the-art training solutions for industrial companies and educational institutions. The Festo Group registered sales of around €3.1 billion (~CDN $4.676 billion) in the 2017 financial year and is represented worldwide at 250 locations with a total of 20,100 employees. About eight per cent of its annual turnover is invested in research and development. Company information available at www.festo.com.

Photo above shows: Festo’s VTUG plug-in valve terminal and CPX-E control system, now available as a package, fit comfortably inside a very small cabinet to minimize project footprints.