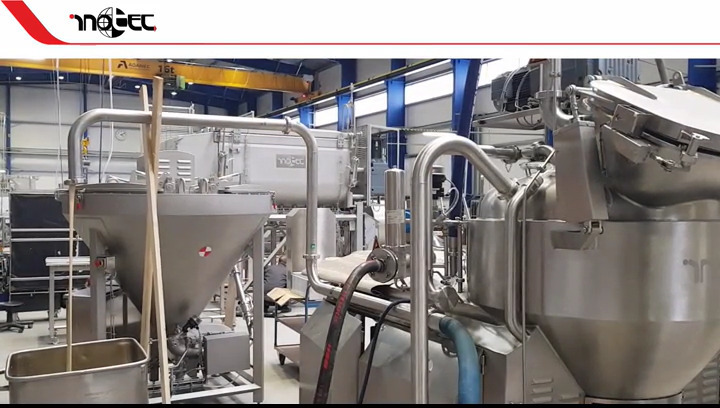

The Handtmann Inotec universal processor with all-in-one batch cooking technology delivers complete, precise processing for a variety of products, including jams, spreads, meat or fish pastes, cheeses, smoothies, sauces, baby foods and more - in one complete and self-contained solution.

Universal Processing PRE-GRINDING / MIXING / COOKING / COOLING / ULTRA-FINE GRINDING / EMULSIFYING / PUMPING

AT THE HEART

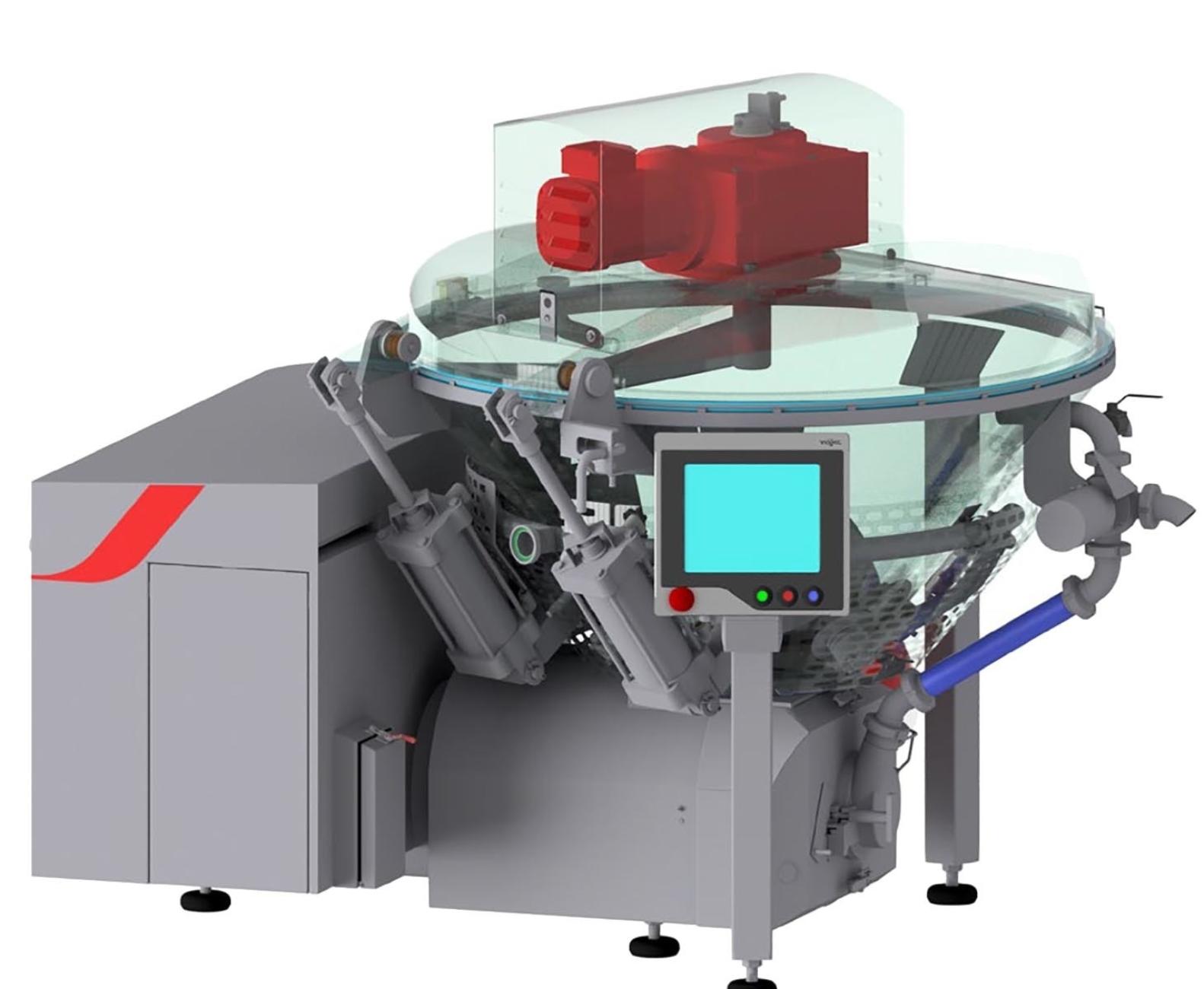

At the heart of our batch cooker is the proven Inotec cutting system with its modular design with 1 to 4 cutting sets. Diced ingredients are reduced in size, blended with liquid and dry ingredients, emulsified, and homogenized. The pre-cutting knives and scraper/agitator comes optionally with variable speed.

AUTOMATIC ADJUSTMENTS

Automatic cutting set adjustment by means of a horizontally movable cutting housing: A computer-controlled servo motor guarantees consistent position adjustment and continuous readjustment of the cutting set.

The product can be heated up by directly injecting steam up to 99°C core temperature. Both options of our Batch cookers, the BC140 and BC175, can be ordered with a double-jacket processing hopper for indirect heating or cooling.

AUTOMATIC PROCESSING

The automatic processing unit I175 is equipped with a vacuum system in order to eliminate air from the product prior to the emulsification process. The vacuum system can also be used to load dry or liquid ingredients. After the heating process, the product goes through the emulsifier cutting set of the BC175 or the BC140 with its modular design in a combination with knife heads and hole plates, also available with variable speed as an option.

The emulsifier can be used to circulate the product as part of the process as well as to discharge to the next stage of production.

For more information

Please enter your email to learn more.