Dust collection in the food industry: Five questions to ask

By Sean Procunier

Food Safety Air filtration system Dust control Editor pick RobeVent

Uncontrolled dust can be a serious concern in the food industry, from both worker safety and food safety perspectives. With different ingredients, processes and applications across the industry, there is no one-size-fits-all solution for food dust. From storing and transporting bulk ingredients to packaging of finished products, your dust control solution must be tailored to your dust, facility and processes. Here are five questions to ask before choosing a dust control solution.

1. Is your dust combustible?

Combustion is by far the most serious risk for many food and ingredient processing facilities. Many of the most common dust types in the food industry—including grain flours, powdered milk, corn starch, wheat starch, sugar, tapioca, whey, cocoa powder and many spices—are considered to be highly combustible. That means they can generate an explosion when allowed to concentrate in the air or inside a dust collection machine, conveyor system or enclosed production area. When working with combustible food dusts, care must be taken to avoid the formation of dust clouds in enclosed spaces and prevent sparks from entering areas where dust may accumulate. Additionally, the dust collector must be equipped with a deflagration system to safely vent the energy of an explosion and prevent pressure waves from propagating back into the facility and generating a secondary (and usually more severe) explosion. Food processing facilities working with combustible dust must perform a dust hazard analysis (DHA).

2. Is your dust hazardous to human health?

Food ingredients may be non-toxic when ingested in appropriate quantities, but that doesn’t mean that it is safe to inhale dust particles from food production processes. Many food dusts (such as flour or sugar) are classified as “nuisance” dusts, which aren’t toxic but can still cause respiratory irritation and inflammation when inhaled in large quantities. Employees with asthma or other lung conditions and employees with allergies to certain ingredients may be at particular risk. Some ingredients, such as certain food additives and flavourings, are more problematic. These ingredients may be toxic when inhaled in occupational quantities. You can minimize worker exposure to nuisance or hazardous dust by enclosing processes and using source capture where possible to prevent dust from spreading through the facility. If dust cannot be adequately controlled using source capture, consider adding a secondary ambient filtration or ventilation system to further diffuse dust.

3. Is cross-contamination a concern in your facility?

Cross-contamination is a significant concern for many facilities processing multiple products and/or ingredients. It may also be important to keep dust from migrating from earlier processes (such as cutting or grinding) to later processes (such as baking or packaging). To avoid cross-contamination between production lines or applications, keep processes enclosed and use an effective source capture solution for each heavy dust-producing process or transfer point. That may mean having separate dust collectors for different parts of the facility or simply using a series of hoods and enclosures all ducted to a centralized industrial dust collection system. Positive and negative pressure zones can be used to further reduce the risk of fugitive dust migrating between processes.

4. What are the physical characteristics of your dust?

The physical characteristics of your dust will impact the design of your dust collection system. Is your dust coarse and abrasive, or is it ultra-fine and hard to capture? How much dust are you producing? Is the dust wet, oily or sticky? Is the dust agglomerative (tending to stick together in masses)? These factors will influence filter selection as well as other aspects of system design such as filter pulsing frequency, air velocity and air-to-cloth ratio (the ratio of air velocity in cubic feet per minute to the area of filter media in square feet).

- Coarse, abrasive dust from seed hulling, milling and grinding may require a dust collector fitted with an abrasive-resistant inlet or drop-out box to protect the filters.

- For ultra-fine dust, you may need a filter with a higher MERV rating, such as a MERV 15 or higher. In some cases, a HEPA after-filter may be added to the dust collector.

- Hygroscopic (moisture-absorbing) dusts can quickly cake onto filters. Coated filters allow more effective shedding of hygroscopic dusts. Other dusts, like sugar dust, may form a solid crust on filters. In these situations, a washable filter medium may be required.

5. How sensitive is your application to fugitive dust?

The importance of dust control will vary between applications. For early-stage applications such as bulk ingredient transport and storage, hulling or milling, some fugitive dust in the environment may be acceptable, as long as it does not create concerns for employee health or comfort, combustion or microbial contamination. At the other end of the spectrum, most packaging environments must be kept pristine—even a small amount of dust outside the inner packaging of a cracker box, for example, may be undesirable. Specialized hoods and positive and negative pressure zones may be needed to maximize dust collection efficiency and keep dust away from sensitive environments.

Selecting the right dust control solution for food applications

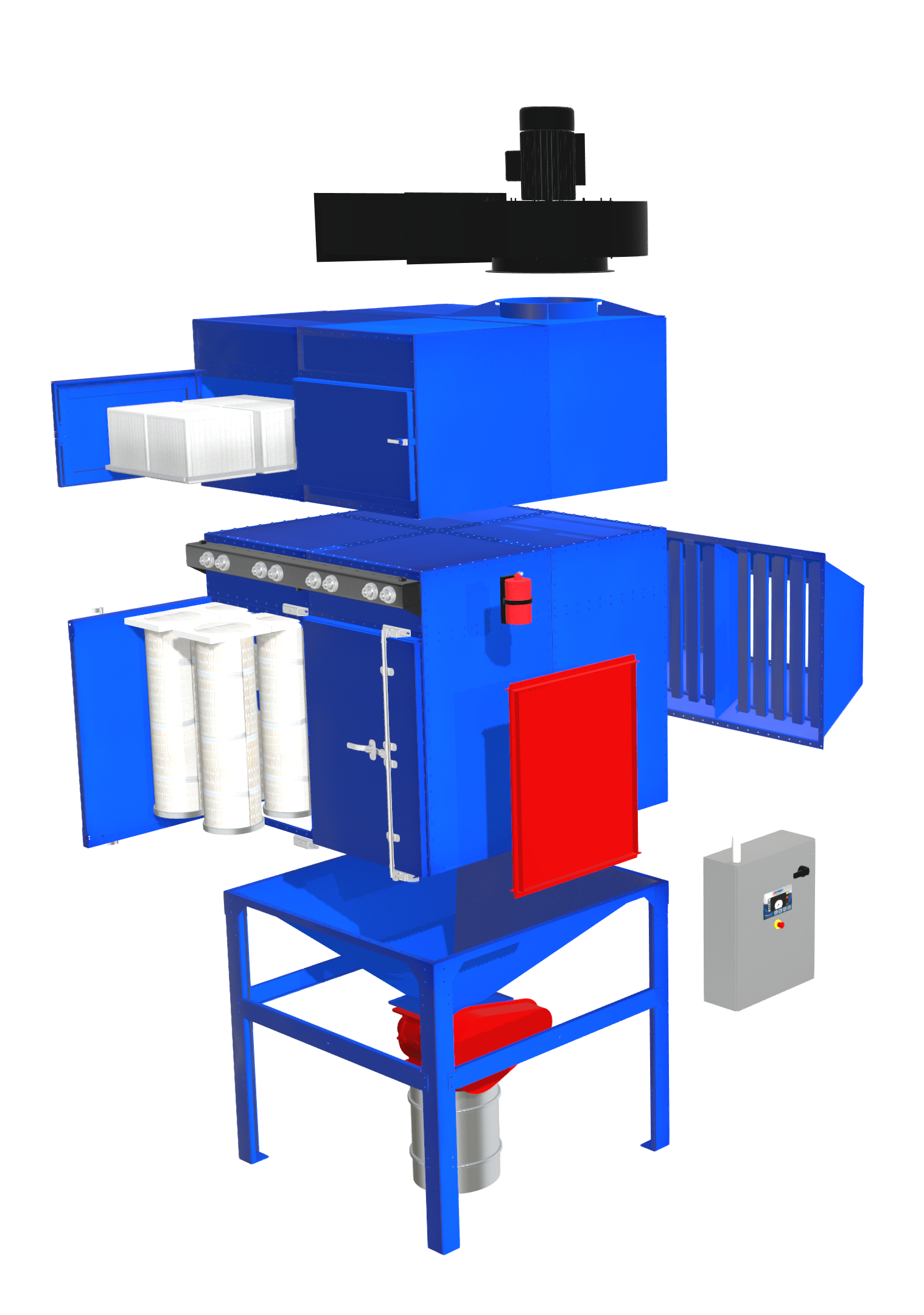

When working with an air filtration system designer, or a dust collection company, make sure they take the time to understand your dust type, processes and requirements. For most facilities, a cartridge-style dust collector provides the best combination of filtration efficiency and performance in the smallest possible footprint. In addition to dust collector selection and placement, system designers will need to consider appropriate hood or enclosure types for each production line or process, ductwork design, the use of positive and negative pressure zones, filter media selection, and the need for secondary air filtration, ventilation or makeup air systems. For complex installations, system designers may even use computational fluid dynamics to understand airflow patterns in the building and how dust collection, ventilation and HVAC systems will all work together to control the flow of dust through the space.

Effective dust control is essential for meeting regulatory requirements, ensuring the safety of food products, and maintaining a safe, comfortable work environment for employees. It’s worth the investment to hire a system designer who will take the time to get it right.

Sean Procunier is country manager – Canada, RoboVent.

Print this page